Iron and steel manufacturing has a long production process, complex process types, many production and discharge links, easily hundreds of emission outlets, thousands of unorganized control points, thousands of vehicles transported every day, coupled with large differences in the level of environmental governance among enterprises, as well as the reliability of the pollution prevention technology of some key links is yet to be verified and other issues, which restricts the realization of the whole process, all-around, full-coverage and full-cycle of the ultra-low emission. Therefore, the implementation of ultra-low emission transformation in the iron and steel industry is not only an important measure to win the battle to defend the blue sky and make up for the short board of environmental protection in the iron and steel industry, but also to force the iron and steel production capacity to the layout of the region with a stronger environmental carrying capacity, and to promote the iron and steel industry to realize high-quality, green development.

Hongdian Steel Plant Ultra-low Emission Digital Mining Solution

The ultra-low emission digital mining solution for Hongdian iron and steel plants collects real-time operating data of intelligent air micro-stations, dust removal and suction equipment, fog machines and other equipment through the intelligent communication terminal developed by Hongdian, realizing grid-based monitoring, smart control and precise management of unorganized dust emissions; establishes a list of pollution sources in the whole plant for key links such as material transportation, material storage and production processes, and connects the data of the flue gas online monitoring system (CEMS) and distributed control system (DCS) through the digital mining platform of Hongdian. By connecting the data of CEMS and DCS, it realizes the intelligent monitoring and dynamic display of the whole process of organized emissions; docking the data of clean transportation access control management system, vehicle electronic ledger, and car washer electronic ledger, it comprehensively evaluates the proportion of clean transportation volume of the enterprise and realizes the scientific evaluation of the performance of the enterprise's ultra-low emission.

System Function

Since the storage, transportation of materials, and the production process of non-organic emissions, organized management, and in-depth management of air pollutants involve multiple systems and equipment, a data collection platform is needed to dock the fragmented subsystems and equipment to achieve data interconnection and unified collection and processing.

1.data interoperability

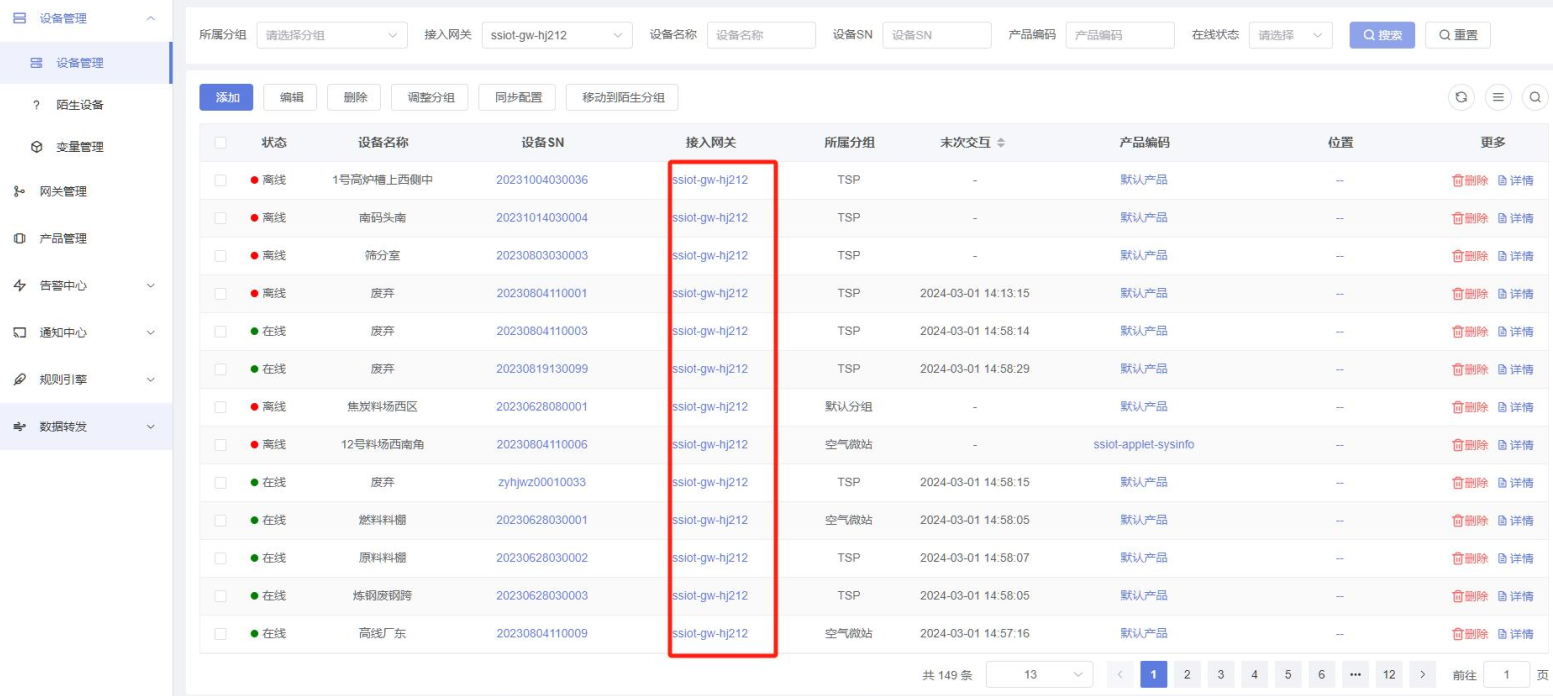

It builds a centralized data collection system through intelligent communication terminals such as Hongdian intelligent gateway, DTU, intelligent controller, and SanSan IoT cloud platform, establishes data governance rules and processes, and effectively ensures the consistency, completeness, accuracy, and security of plant data. It opens up the data of CEMS and DCS to realize the data linkage of the whole process monitoring of organized emissions, three-dimensional networked intelligent monitoring of disorganized emissions, and intelligent linkage management system and clean transportation system. It provides open interfaces such as MQTT/HTTP/DB to realize data sharing and synergy of the integrated application system of control and governance.

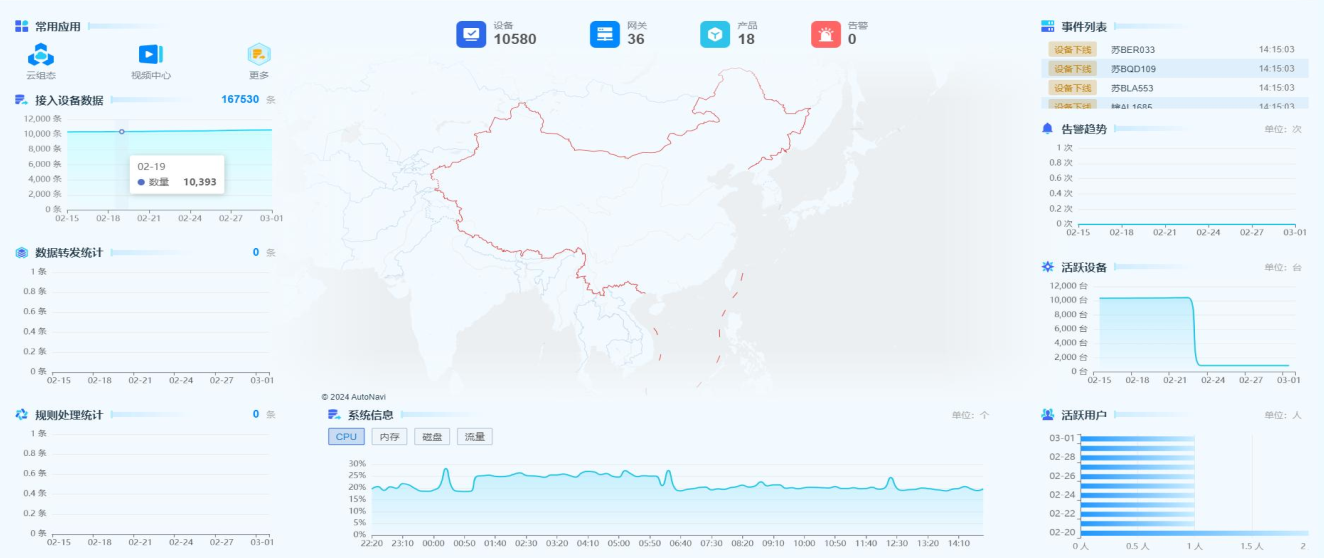

2. Visualization

A graphic global display, including the total number of access devices in the whole plant, data forwarding statistics, alarm events, and alarm trends, support for adding, deleting, changing, and checking all the monitoring, surveillance, governance, and other front-end hardware equipment ledger information.

3. Intelligent monitoring of disorganized emissions

It establishes a list of unorganized emission sources with full coverage of key aspects such as closed storage of materials, closed transportation of materials, closed storage and transportation of materials, and production process, and keeps it updated once a year. The platform supports the environmental protection HJ/T212-2017 protocol and can access a large number of TSP terminals, air micro-stations, dust monitors, VOC monitors, and other sensors for emission monitoring of ambient air, TSP and other data, and realize the precise management of the disorganized emissions through the HTC AI Intelligent Convergence Gateway linking the intelligent fog machine, dust removal and dust suction equipment, cloud mist system and other management equipment.

4. Dust monitoring and analysis

Key polluted areas such as inside and inside the silo, import and export, blast furnace roof, blast furnace ore chute, sintering ring cooling, top of the steelmaking workshop, and other locations to add video cameras, eagle eyes, dome, and so on to build the dust monitoring system, through the macro-electric AI intelligent convergence gateway based on GB28181, Onvif and other protocols access to the camera or NVR, real-time capture or take streams, the operation and the process of raising the dust of the video analysis and monitoring records.

5.Management of clean transport vehicles

Docking access control video monitoring system, pre-entry of vehicle information that meets the requirements of the National VI and above or new energy vehicles, each lane are individually equipped with cameras for monitoring and remembering the transport vehicles through the gate in and out of the factory, to achieve the logistics vehicles, transport vehicles in and out of the filing management and cleaning situation intelligent capture for the logistics and transportation of the enterprise to provide intelligent, automated, information-based management.

Application Products

Hongdian Intelligent Controller is an intelligent terminal integrating communication, acquisition, and control. It has built-in rich industrial protocols, quickly accesses industrial equipment with standard protocols, efficiently completes access to decentralized equipment, and data acquisition, and supports protocol customization.

Hongdian AIoT Gateway is an intelligent and highly available integrated edge node that combines control, edge analysis, communication, and AI capabilities with multiple types of interfaces, incorporating Hongdian's self-developed Al algorithmic model, and supporting structured analysis of multi-channel 1080P HD video.

With a deeply optimized Data Terminal Unit from Hongdian, the terminal supports 3G/4G/5G networks and a 1.8GHz power network band, stable data connection, and industrial-grade standard design, it can adapt to various complex and harsh on-site environments.

Hongdian Industrial Smart IOT Gateway has powerful data acquisition, storage, analysis, and processing capabilities; it is equipped with features such as a full 5G frequency band, high-precision timing, 5G LAN, etc.; it is rich in interfaces with strong scalability and supports 300+ mainstream industrial protocols parsing, which meets the needs of data acquisition from diversified equipment.

Hongdian's ultra-low emission digital mining solution for iron and steel plants helps enterprises establish a perfect monitoring system, solves the problems of high transformation cost of organized emissions, difficult iteration of environmental protection equipment, and difficult treatment of disorganized emissions with multiple and scattered links, and helps iron and steel enterprises truly realize ultra-low emission reduction at the source, process control, and systematic management through the whole-process, all-encompassing, full-coverage, and full-cycle monitoring and management.